Producing such items displayed requires the construction of Jigs and Templates

This presentation is not about purchasing Jigs, as they are not readily available, it is about making your own, in your own workshop.

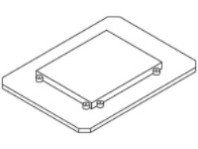

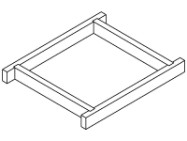

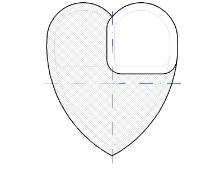

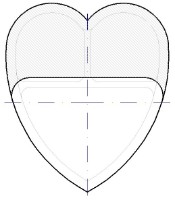

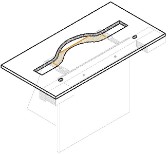

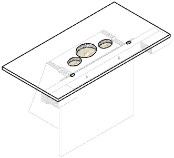

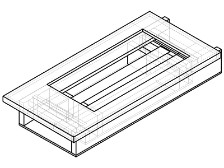

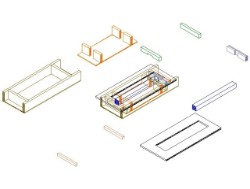

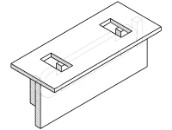

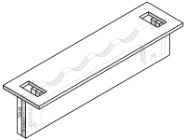

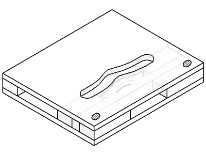

The two jigs above require some form of box construction to prevent the material from moving during the process. The two boxes I have constructed are 400mm x 300mm x 40mm, and 300mm x 300mm x 40mm

These boxes are used extensively to produce a number of routing processes and are referred to as

'Jig Holders'

throughout this presentation

When making the decision to produce any project, careful consideration should be given as to the method of construction to be used. As this is a routing project I suppose the first suggestion is to see if it can be achieved with the router in the router table or it may be necessary select other tools or machinery to complete the various stages of construction.

No matter what method is selected it has to be done with SAFETY as the main factor

To Contact the author email; tomann-at-iinet-dot-net-dot-au

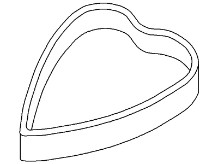

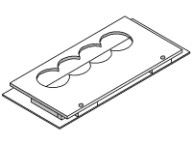

The Heart shaped box presented below is only a sample of a number of projects that can only be constructed after a Jig Holder is produced, and with the aid of Templates, and template guides.

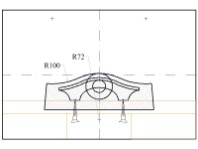

Mantle Clock;

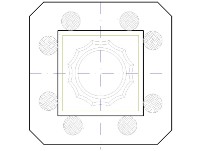

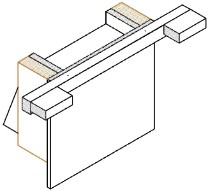

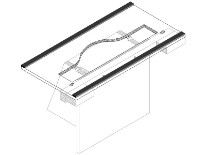

With a change in project will mean a change in how we go about setting it up in a jig and producing templates

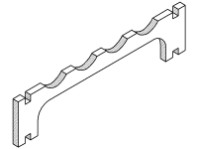

It has been necessary to look at alternative methods of holding material secure during the routing process. This particular Jig can be inserted into the bench vice to hold it secure. Also in the first template strips are added to support the router (with the aid of router support rods) especially during the second stage routing the face of the clock. These will prevent the router from 'Tipping' into the recess when making the cut.

Note; This particular clock was produced by a number of V.I.Ps (Vision Impaired Persons) at the Association for the Blind in Western Australia

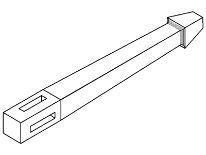

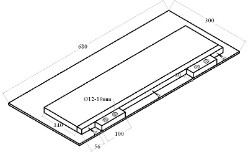

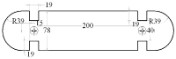

Producing table or Chair legs:

Once upon a time we would not consider producing tapered legs as we did not possess a planer to make the tapers. This method is still used today as it is considered the proper method to follow. Some may consider this process can be completed with the router in the router table and I have no doubt it can. With a liitle more consideration a box like jig can be produced to support the material and the shape can be produced with the router in the plunge mode with Greater safery Awareness

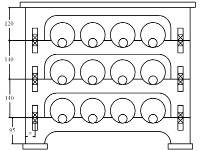

Many ideas will spring to mind once a firm understanding on how the template guides are to be used. The 12 bottle wine rack design was taken from a routing magazine some years ago where it was demonstrated on how the small CNC router could be used to produce the parts

Selecting a different approach to solving the problems with greater Safety Awareness, members of the class were able to achieve more interesting projects

Each one of the projects I have submitted have been completed with the router used mainly in the plunge mode. I am convinced that a greater number of projects can be achieved when the router is used in this mode, not to forget the greater safety awareness that is achieved also. Many of the processes I have used to produce the projects are not capable of producing on the router table (IMHO)

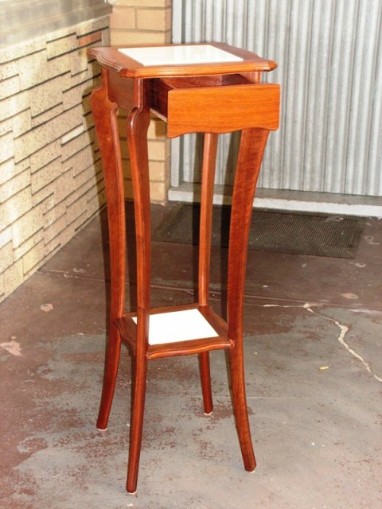

To illustrate the advantages of using the Template Guides and constructing Jigs and Templates consider the Pedestal project listed below

There is no doubt a 'Band Saw ' could play a major roll in shaping the legs and rails and a Drop Saw / Mitre Saw, would be the tool to use to cut the mitres required. When this was presented to the class at the Association for the blind these machines had to be discarded due to safety reasons, therefore a number of jigs and template were required for the clients to produce this pedestal with Safety

Also to be taken into consideration, was the method of producing the necessary joints required for the construction

This project has been highlighted to illustrate that it can be achieved with the router, especially if we do not have the 'Band Saw' or 'Drop / Mitre saw' in our work shop. Not only is use of the template guides considered safe for the blind clients, it will also introduce New routing Techniques to allow the average wood worker to use the router with more confidence. The router table has not been used to complete this project. Note; To add the mouldings to the edges of the various parts I had to introduce an alternative method which added greater safety awareness. (Overhead Routing)

There is a great deal more that can be written on how this project was completed, this is one of my projects that has been produced but I still require to write the procedures describing the method I have used

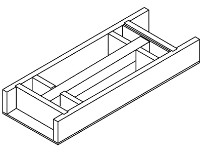

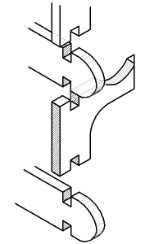

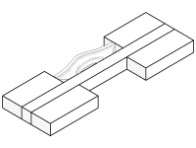

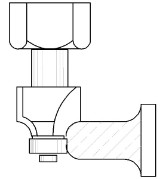

Cabinet Handles (Wooden)

Cabinet handles may not be available in the same material as the cabinet you are in the process of construction so why not make your own simply by constructing a simple jig and a couple of templates

Other handle designs are available for routing with safety